Bulk Bag Discharger Solutions

Safe & Efficient Bulk Bag Unloading

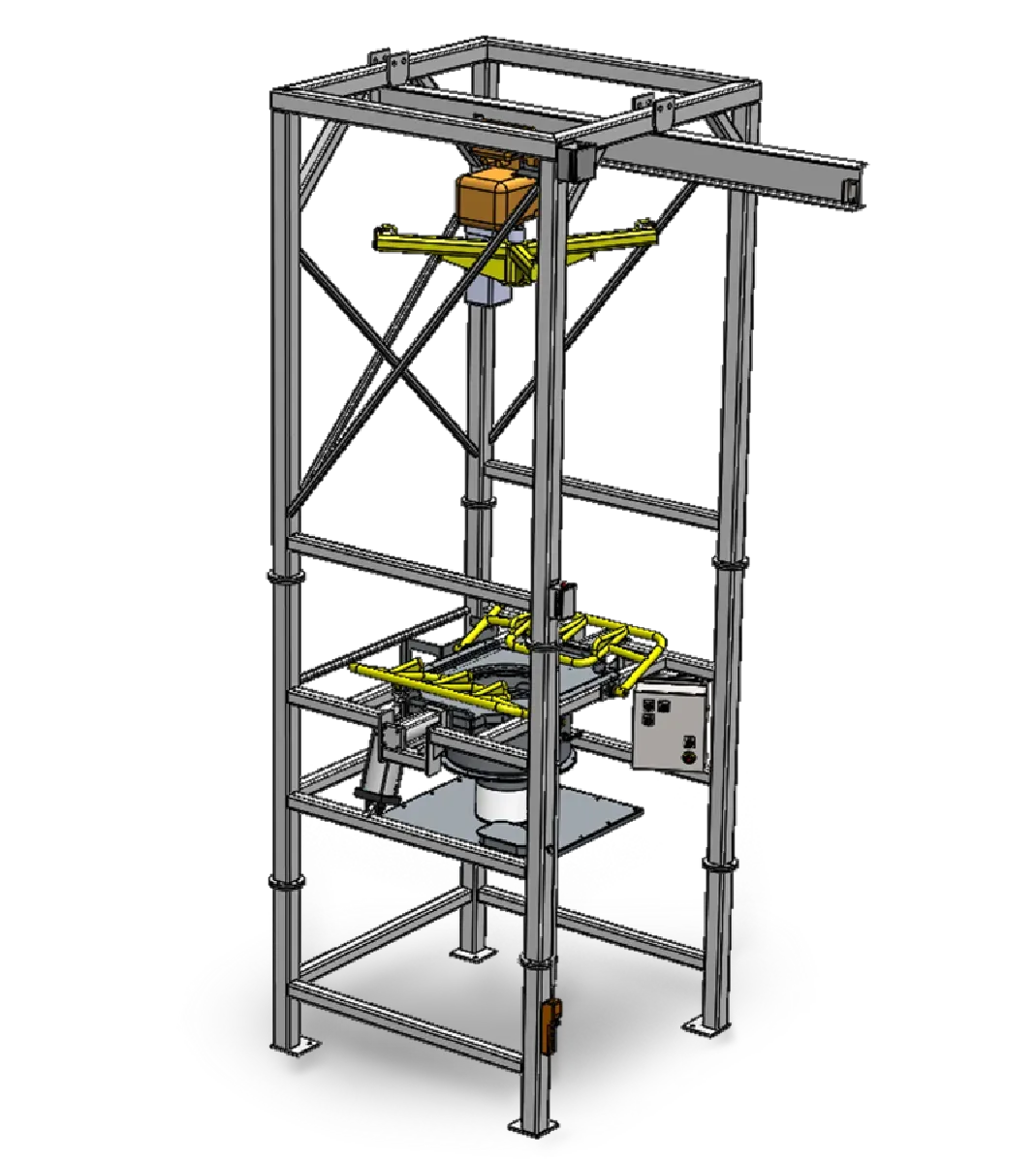

Introducing our Bulk Bag Discharger

Designed for optimal material unloading, our patented Material Master® Bulk Bag Discharger offers exclusive features and benefits. With advanced flow promotion, secure discharge spout closure, and effective dust control, our dischargers ensure efficient unloading. Prioritizing safety and reliability, these dischargers minimize downtime and maximize productivity.Contact us at 269.673.2125 or fill out a form to learn more about our high-performing dischargers.

Controls

Discharge Options (Feeders, Screw Coveyors, Etc.)

Hoist Options

Flo-Lock Gate

Flo-Master Massagers

Seal-Master Bag Spout Access Chamber

Featured Components

- Controls

- Discharge Options

- Hoist Options

- Flo-Lock Gate

- Flo-Master Massagers

- Seal-Master Bag Spout Access Chamber

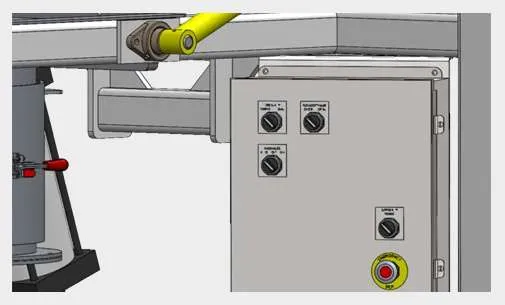

Controls

Locally mounted control panel, ergonomically located, providing easy access to exclusive feature controls. Controls customizable for any operating environment.

Discharge Options (Feeders, Screw Coveyors, Etc.)

Modular design provides integration flexibility, customized to include material handling and processing equipment, engineered to meet your specific production requirements.

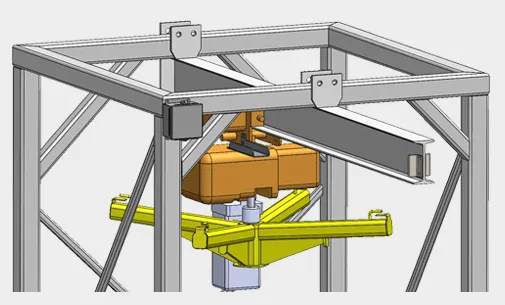

Hoist Options

Harrington hoists set the standard for performance and reliability. Energy chain protects power and pendant cords, pendant plugs into junction box on lower frame to prevent tangles. Spider-Lift™ bulk bag lifting frame is easy to use, accepts a wide range of bag sizes, and requires less overhead clearance.

Flo-Lock Gate

Flo-Lock gate provides reliable shut off of material flow. Gate stops flow of materials in applications where iris valves, pneumatic pinch bar systems, or articulated rod type gates may jam, break, or fail to halt material flow. Ideal for partial bag discharging, it allows a partially discharged bag to be re-tied and removed from the discharger.

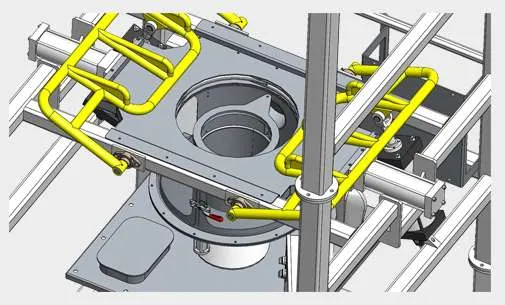

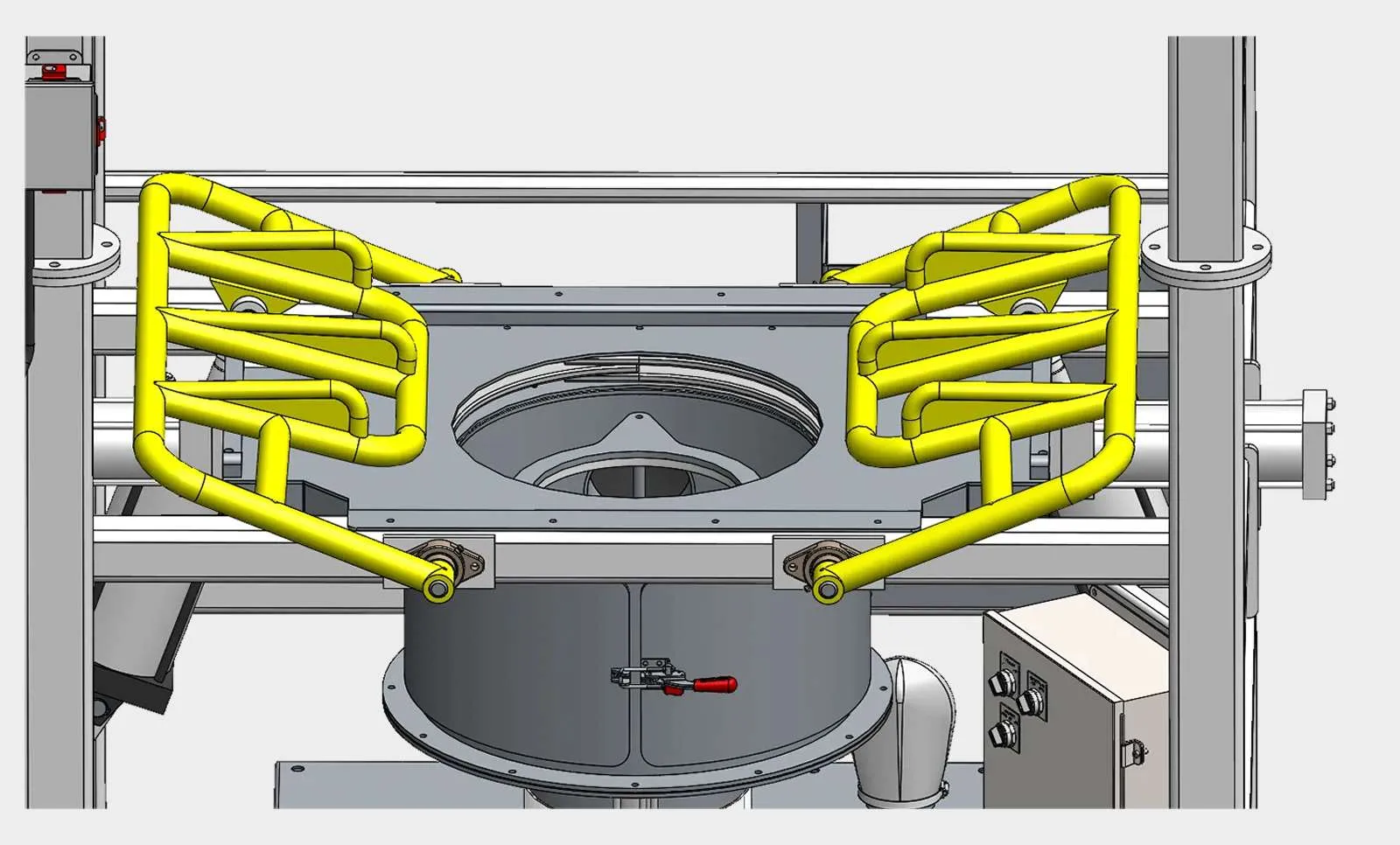

Flo-Master Massagers

Two (2) powerful pneumatic cylinders actuate two (2) heavy-duty tubular massaging frames. The massaging frames, located on opposing lower sides of the bulk bag, raise and lower the bottom of the bag, elevating and pushing material into the flow path. Massaging frames pivot on 1” diameter shafts with pivot bearings. System includes adjustable timer controls.

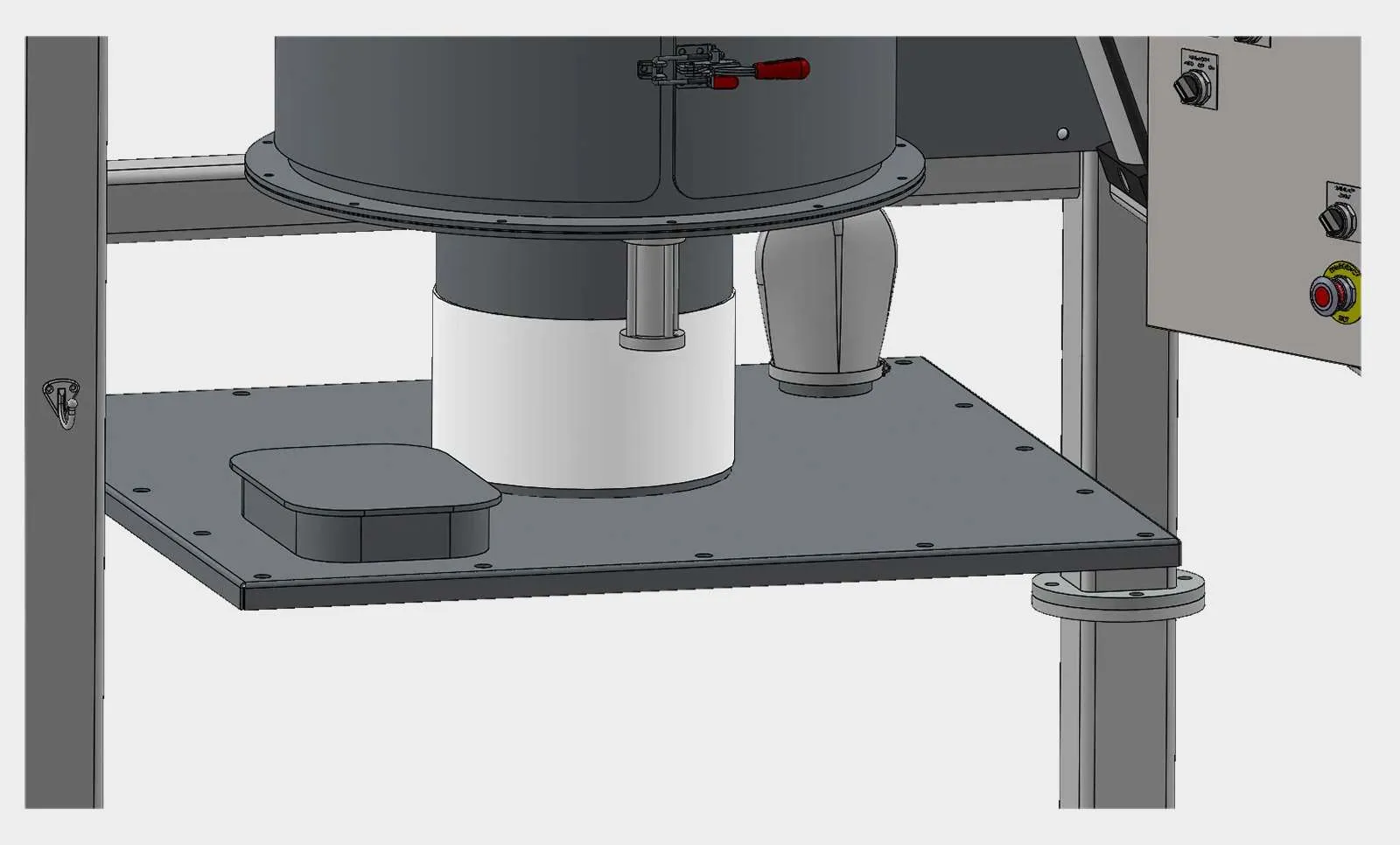

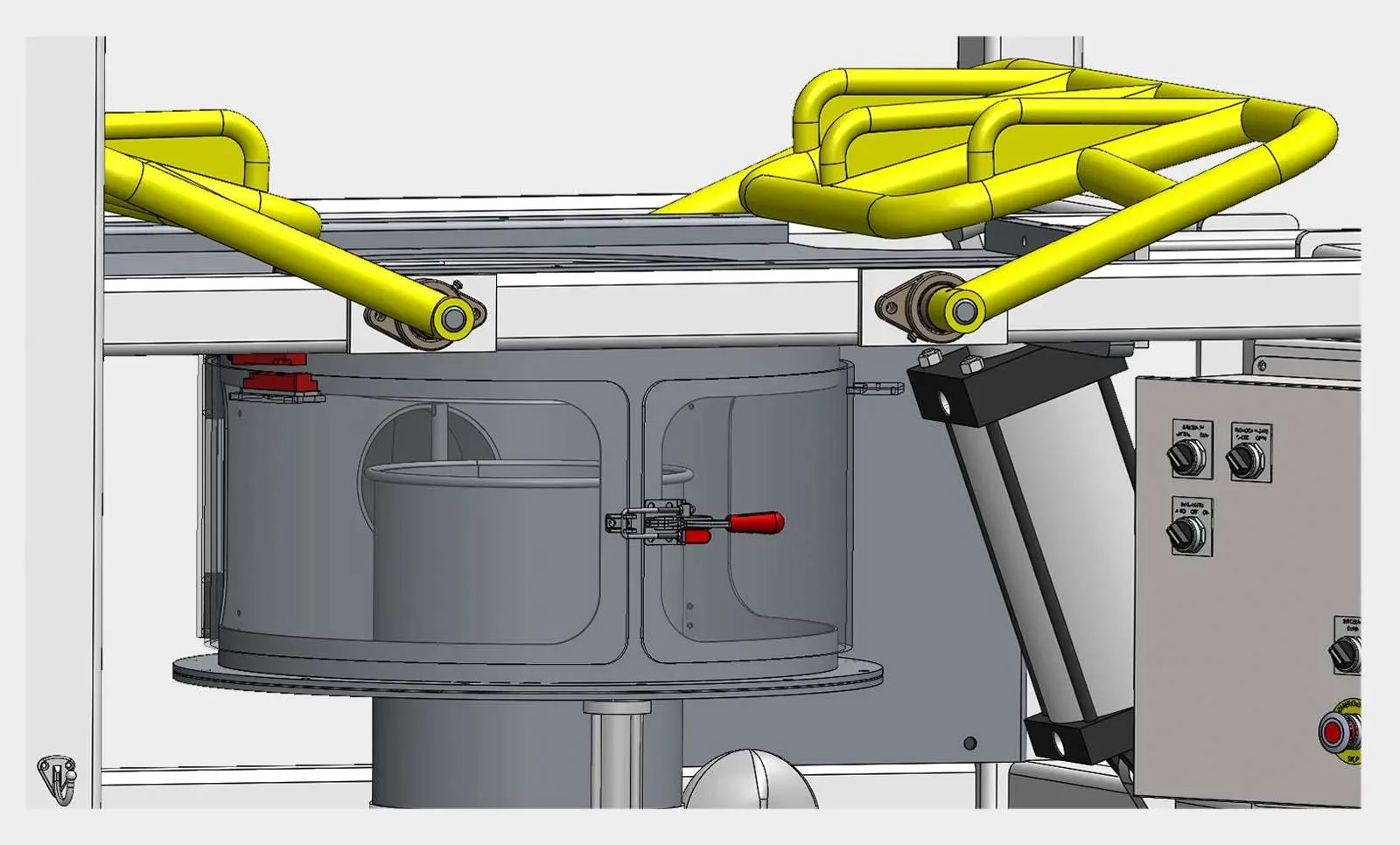

Seal-Master Bag Spout Access Chamber

MTS exclusive Seal-Master™ round bag spout chamber includes “gull wing” doors which are designed to swing out of the operator’s way, providing enhanced bulk bag discharge spout access for easy release of the bag tie. Each door has a compression seal to ensure a dust-tight seal when in the closed, secured position.

Featured

Components

Hoist Options

Harrington hoists set the standard for performance and reliability. Energy chain protects power and pendant cords, pendant plugs into junction box on lower frame to prevent tangles. Spider-Lift™ bulk bag lifting frame is easy to use, accepts a wide range of bag sizes, and requires less overhead clearance.

Flo-Lock Gate

Flo-Master Massagers

Seal-Master Bag Spout Access Chamber

MTS exclusive Seal-Master™ round bag spout chamber includes “gull wing” doors which are designed to swing out of the operator’s way, providing enhanced bulk bag discharge spout access for easy release of the bag tie. Each door has a compression seal to ensure a dust-tight seal when in the closed, secured position.

Watch Now: Material Master® Bulk Bag Discharger

Experience the high-performance of our bulk bag discharger.

Showcasing Our Featured Bulk Bag Dischargers

Explore our featured bulk bag dischargers and learn how Material Transfer can design a custom solution to meet your unique needs.

Featured

Equipment

#7855-AE-2 Bulk Bag Discharger

Equipped with two (2) Spider-Lift™ bulk bag lifting frames, this bulk bag discharger can load a bag of material within the frame while staging the next bag. Designed to handle powder-form drink mix for the food & beverage industry, this unit is customized with all stainless-steel product contacts and FDA-rated paint.

#7236-AE Bulk Bag Discharger

This stainless-steel bulk bag discharger was engineered with one word in mind: sanitation. Built to handle granulated sugar for a pharmaceutical processing company. Due to the washdown requirements of this environment, we included a tool-less, quick-clean Seal-Master™ chamber design to ensure that product contact surfaces could be easily disassembled. We used an intrinsically safe system for air logic controls to eliminate the need for any electrical components.

#10173-AE Bulk Bag Discharger

Designed to handle cake and pancake mix, this bulk bag discharger was engineered to promote material flow and transfer product from bulk bags to the customer’s existing system. Heavy-duty Flo-Master™ breaker-bar massagers ensure the material leaves the bulk bag, traveling down through the transition and into the 12-cubic-ft volume below. An electric vibrator ensures material flow within the hopper as it flows into the screw conveyor, traveling to a height of almost 10ft where the material is fed into the customer’s existing system.

#7855-AE-2 Bulk Bag Discharger

Equipped with two (2) Spider-Lift™ bulk bag lifting frames, this bulk bag discharger can load a bag of material within the frame while staging the next bag. Designed to handle powder-form drink mix for the food & beverage industry, this unit is customized with all stainless-steel product contacts and FDA-rated paint.

#7236-AE Bulk Bag Discharger

This stainless-steel bulk bag discharger was engineered with one word in mind: sanitation. Built to handle granulated sugar for a pharmaceutical processing company. Due to the washdown requirements of this environment, we included a tool-less, quick-clean Seal-Master™ chamber design to ensure that product contact surfaces could be easily disassembled. We used an intrinsically safe system for air logic controls to eliminate the need for any electrical components.

#10173-AE Bulk Bag Discharger

Designed to handle cake and pancake mix, this bulk bag discharger was engineered to promote material flow and transfer product from bulk bags to the customer’s existing system. Heavy-duty Flo-Master™ breaker-bar massagers ensure the material leaves the bulk bag, traveling down through the transition and into the 12-cubic-ft volume below. An electric vibrator ensures material flow within the hopper as it flows into the screw conveyor, traveling to a height of almost 10ft where the material is fed into the customer’s existing system.

Integrated Systems: Streamlined Material Handling Operations

Experience seamless material handling with Material Transfer’s integrated systems, featuring our high-performing dischargers at the core. By combining our reliable dischargers with advanced auxiliary equipment, we deliver custom solutions to optimize your entire material handling operation.

Reliable Service & Parts

Our comprehensive range of service and parts includes installation and support, maintenance, aftermarket parts and on-site assistance. Maximize the performance and longevity of your equipment with our reliable service and parts solutions.