Drum Dischargers

Streamlined Drum Unloading

Experience our Drum Dischargers

Designed for efficient material handling, our custom drum dischargers safely unload materials into a variety of processing equipment. We custom engineer reliable drum discharge solutions to relieve worker strain, improve plant cleanliness, and ensure smooth performance. Leverage our drum dischargers to optimize your bulk material unloading today.

Contact us at 269.673.2125 or fill out a form to learn more about our high-performing dischargers.

Controls

Discharge Angles

Discharge Options (Valves, Feeders, Etc.)

Dust-Tight (Lift & Seal™) or Open Discharge

Equipment construction & finishes

Hydraulic Systems

Featured Components

- Controls

- Discharge Angles

- Discharge Options (Valves, Feeders, Etc.)

- Dust-Tight (Lift & Seal™) or Open Discharge

- Equipment construction & finishes

- Hydraulic Systems

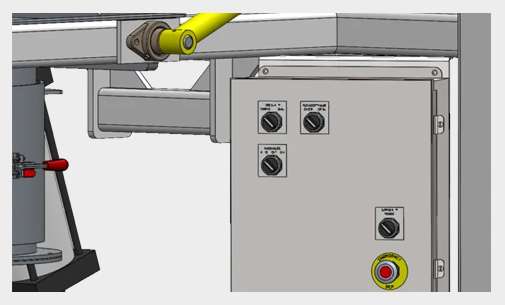

Controls

Locally mounted controls provide quick access to critical operational parameters and discharging process status. Controls customizable for any operational environment.

Discharge Angles

Exclusive designs provides smooth rotation up to 180° for maximum material discharge.

Discharge Options (Valves, Feeders, Etc.)

MTS offers a wide range of valves and integrated solutions to match your needs. Valves provide complete product containment during the discharging cycle. Each system is engineered to provide optimal discharge performance when handling your specific material.

Dust-Tight (Lift & Seal™) or Open Discharge

MTS exclusive Lift & Seal System™ seals the drum to a closed pour hood to prevent contaminants from entering the process. Open discharge options available for processes where containment is not critical.

Equipment construction & finishes

Specific to each application, Material Transfer offers a wide range of materials, finishes, and paints to ensure the customer’s requirements are met. Our durable construction and corrosion resistant finishes will provide you with equipment to withstand the plant environment, whether it be a food packaging facility or a chemical treatment plant.

Hydraulic Systems

Premium-quality Parker hydraulic systems with custom-sized power units capable of handling process specific rate requirements.

Featured

Components

Discharge Options (Valves, Feeders, Etc.)

MTS offers a wide range of valves and integrated solutions to match your needs. Valves provide complete product containment during the discharging cycle. Each system is engineered to provide optimal discharge performance when handling your specific material.

Equipment construction & finishes

Specific to each application, Material Transfer offers a wide range of materials, finishes, and paints to ensure the customer’s requirements are met. Our durable construction and corrosion resistant finishes will provide you with equipment to withstand the plant environment, whether it be a food packaging facility or a chemical treatment plant.

Showcasing Our Featured Drum Dischargers

Explore our featured drum dischargers and learn how Material Transfer can design a custom solution to meet your unique needs.

Featured

Equipment

#9037-AC Drum Dumper

This Lift & Seal™ hydraulic drum dumper was designed for handling drums filled with precious metals. Automatic controls were used to index the drum in and out of the discharger without manual assistance. With a 180° dump-carriage rotation, this unit accomplishes maximum material discharge with each cycle.

#9276-AC Drum Dumper

To discharge drums containing plastic additives, we designed this caster portable, intrinsically safe Lift & Seal™ drum dumper. The drum is raised to form a dust-tight seal between the drum and the fixed pour cone, preventing contaminants from entering into the product during discharge. Indoor-use portability includes two rigid casters and two locking swivel casters with face contact brakes to prevent movement once in place.

#6330-AC Drum Dumper

Catering to the chemical industry, this Lift & Seal™ drum dumper provides a solution to move maximum product with minimal product contact. With a 600lb capacity, 60” discharge height, and 180° dump carriage rotation, this drum discharger offers maximum results for heavy, repetitive processes, keeping workers safe and production up and running.

#9037-AC Drum Dumper

This Lift & Seal™ hydraulic drum dumper was designed for handling drums filled with precious metals. Automatic controls were used to index the drum in and out of the discharger without manual assistance. With a 180° dump-carriage rotation, this unit accomplishes maximum material discharge with each cycle.

#9276-AC Drum Dumper

To discharge drums containing plastic additives, we designed this caster portable, intrinsically safe Lift & Seal™ drum dumper. The drum is raised to form a dust-tight seal between the drum and the fixed pour cone, preventing contaminants from entering into the product during discharge. Indoor-use portability includes two rigid casters and two locking swivel casters with face contact brakes to prevent movement once in place.

#6330-AC Drum Dumper

Catering to the chemical industry, this Lift & Seal™ drum dumper provides a solution to move maximum product with minimal product contact. With a 600lb capacity, 60” discharge height, and 180° dump carriage rotation, this drum discharger offers maximum results for heavy, repetitive processes, keeping workers safe and production up and running.

Integrated Systems: Streamlined Material Handling Operations

Experience seamless material handling with Material Transfer’s integrated systems, featuring our high-performing dischargers at the core. By combining our reliable dischargers with advanced auxiliary equipment, we deliver custom solutions to optimize your entire material handling operation.

Reliable Service & Parts

Our comprehensive range of service and parts includes installation and support, maintenance, aftermarket parts and on-site assistance. Maximize the performance and longevity of your equipment with our reliable service and parts solutions.