Bulk Bag Conditioners

Advanced Conditioning Solutions

Experience our Bulk Bag Conditioners

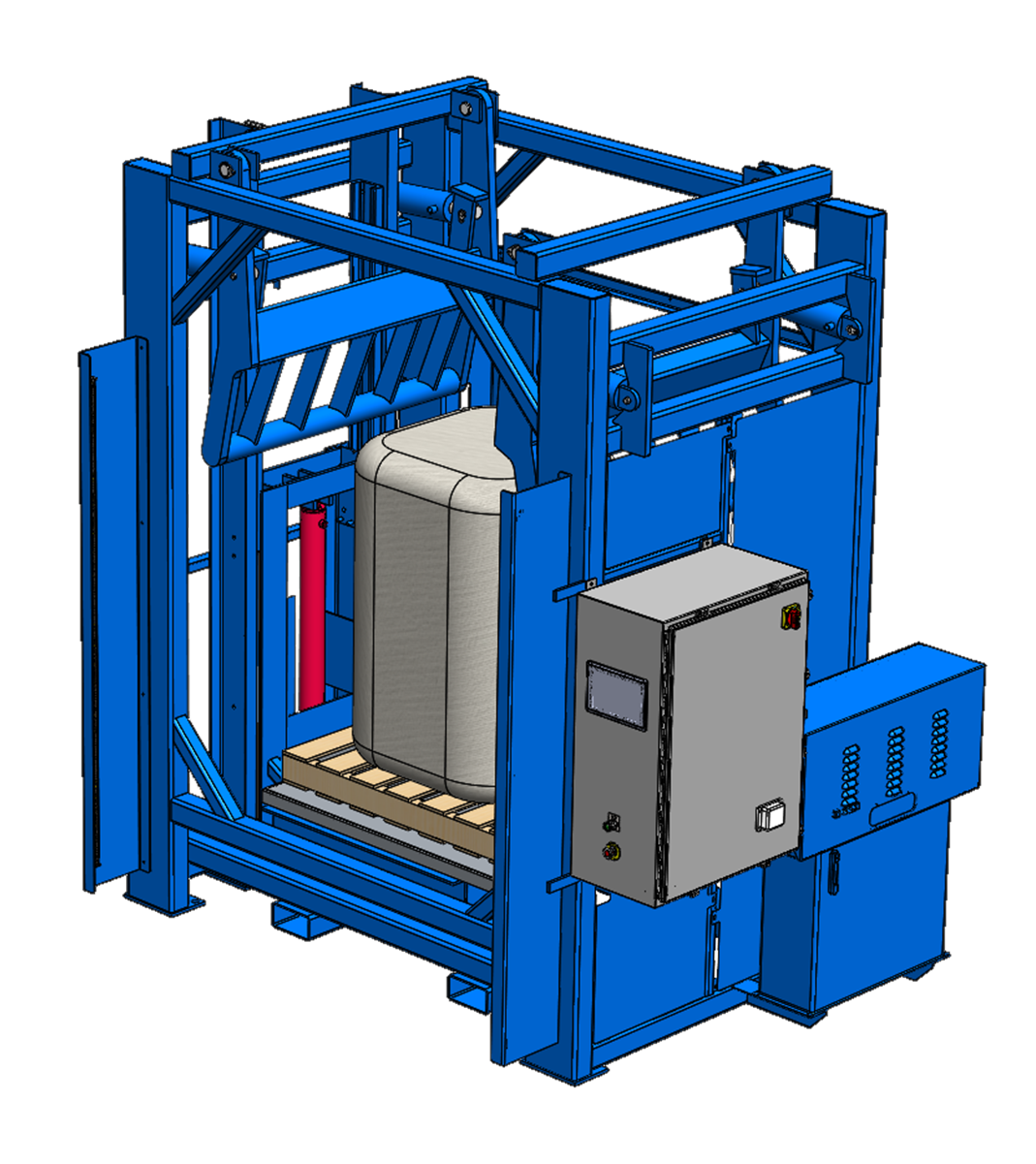

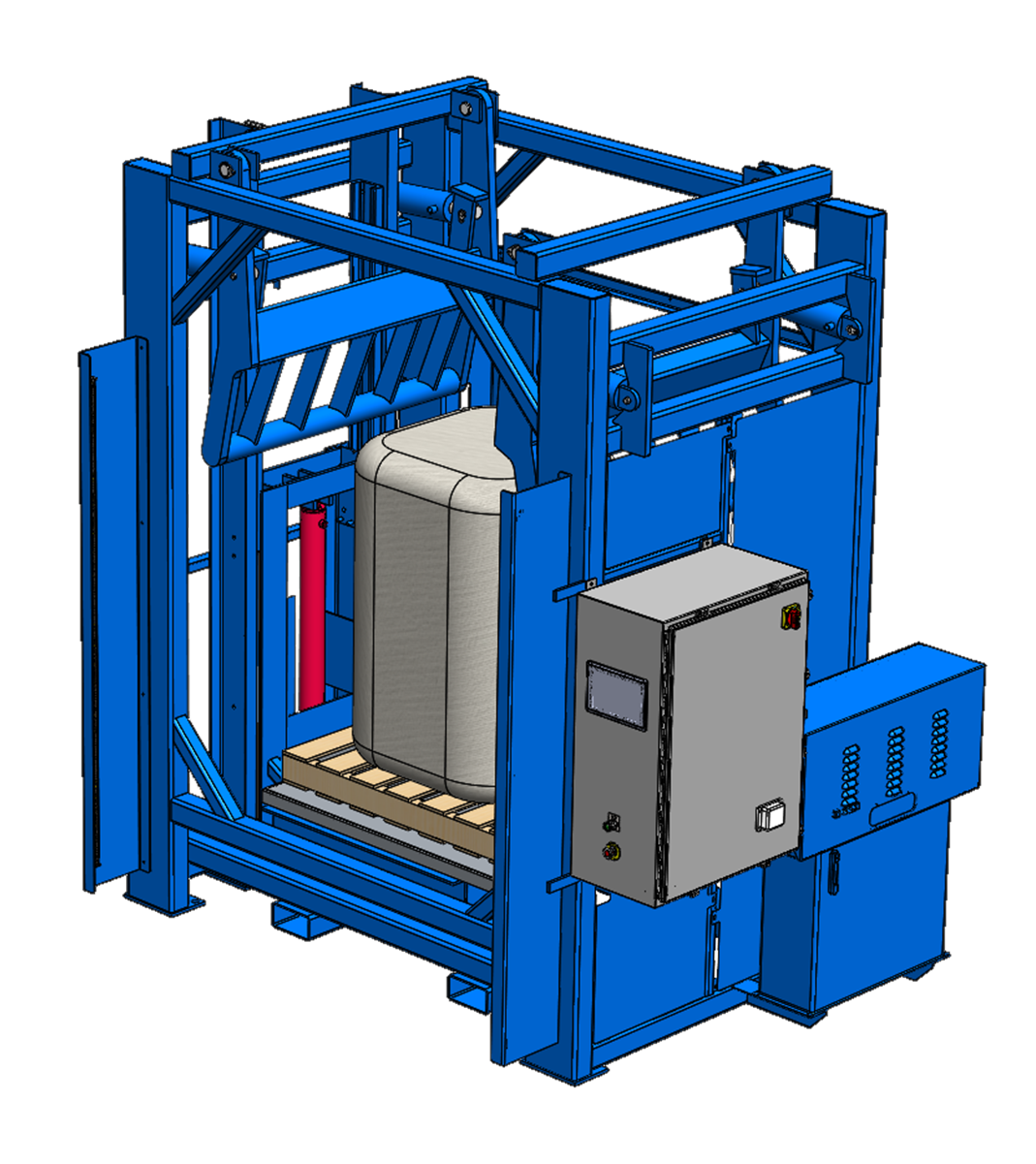

With its patented design and unique feature set, the Material Master® Bulk Bag Conditioner safely and seamlessly returns hardened bulk bags to a free-flowing state. Our custom bulk bag conditioners are designed to meet your unique application requirements and optimize your entire conditioning process.

Contact us at 269.673.2125 or fill out a form to learn more about our advanced conditioners.

Conditioning Arms

Conditioning Frame

Control Systems

Hydraulic Systems

Hydraulic Lift Platform

Machine Guarding

Featured Components

- Conditioning Arms

- Conditioning Frame

- Control Systems

- Hydraulic Systems

- Hydraulic Lift Platform

- Machine Guarding

Conditioning Arms

Driven with 75,000 pounds of cylinder force to condition even the most severely agglomerated materials. Pivoting conditioning arms fracture and shear materials for superior results. Design eliminates troublesome horizontal guide rod binding and deflection. Arms built from heavy wall structural tube and carbon steel plate.

Conditioning Frame

The industry’s most compact footprint. Heavy-duty 4” x 10” structural carbon steel tube main frame with gussets and continuous welds. Designed utilizing Finite Element Analysis for safety and durability.

Control Systems

Easily creates recipes for your material in minutes from pre-loaded templates. Eliminates production bottlenecks by providing consistent conditioning results. User configurable parameters for your specific requirements.

Hydraulic Systems

Premium quality Parker hydraulic system with dual 5 GPM pumps, 10 HP pump motor with a 30-gallon carbon steel reservoir, 4 station manifold, sight gauge, pressure relief valve and plated steel hydraulic fittings.

Hydraulic Lift Platform

48” vertical travel, 4,000-pound capacity, heavy-duty, 48” square rotary turntable with manual rotation or robust powered drive and hydraulic lift cylinder with adjustable axial bearings traveling within a hevi-rail track.

Machine Guarding

Typical options include clear polycarbonate or acrylic panels, perforated, expanded or sheet metal panels, twin electrically-interlocked loading doors, load-side light curtains and safety scanners.

Featured

Components

Conditioning Arms

Driven with 75,000 pounds of cylinder force to condition even the most severely agglomerated materials. Pivoting conditioning arms fracture and shear materials for superior results. Design eliminates troublesome horizontal guide rod binding and deflection. Arms built from heavy wall structural tube and carbon steel plate.

Watch Now: Material Master® Bulk Bag Conditioner

Designed to transform operations, our patented Material Master® Bulk Bag Conditioner delivers the efficiency and high-performance we’re known for.Showcasing Our Featured Bulk Bag Conditioners

Explore our featured bulk bag conditioners and learn how Material Transfer can design a custom solution to meet your unique needs.

Featured

Equipment

#10151-MC Bulk Bag Conditioner

Materials such as salt and sugar can harden over time due to multiple environmental factors, including humidity or road travel. Designed for use in the food industry, this bulk bag conditioner is built to return these materials back to a free-flowing state without compromising the bulk bag or the material itself. With features including a stainless-steel turntable cover and food-grade grease, this unit offers superior results while maintaining sanitary requirements of the facility.

#10143-MC Bulk Bag Conditioner

This bulk bag conditioner was built for use in the medical industry. With a 48” travel hydraulic lift platform, it can handle a range of bulk bag sizes. A custom recipe can be created to handle dimensions of each bag and saved for future use so that operations are completely automated, reducing risk of operator error or inexperience. To protect the safety of the operator, this conditioner includes metal guarding on three sides and load-side light curtains that seize equipment operation if the sensor is tripped.

#10088-MC Bulk Bag Conditioner

The purpose of our bulk bag conditioners is to deliver the same end result – free-flowing material – but there are many ways to customize your unit to fit your facility’s needs. This construction materials manufacturer needed a durable unit with chemical-resistant fabrication that could operate continuously throughout 24-hour shifts, all while maintaining a clean and safe facility. To meet their requirements, we designed this unit to include a stainless-steel turntable cover (chemical resistance), a fan-driven hydraulic oil cooler (continuous operation), a drip-pan below the hydraulic unit (cleanliness), and four sides of operator protection including three sides of metal guarding and load-side light curtains (safety).

#10151-MC Bulk Bag Conditioner

Materials such as salt and sugar can harden over time due to multiple environmental factors, including humidity or road travel. Designed for use in the food industry, this bulk bag conditioner is built to return these materials back to a free-flowing state without compromising the bulk bag or the material itself. With features including a stainless-steel turntable cover and food-grade grease, this unit offers superior results while maintaining sanitary requirements of the facility.

#10143-MC Bulk Bag Conditioner

This bulk bag conditioner was built for use in the medical industry. With a 48” travel hydraulic lift platform, it can handle a range of bulk bag sizes. A custom recipe can be created to handle dimensions of each bag and saved for future use so that operations are completely automated, reducing risk of operator error or inexperience. To protect the safety of the operator, this conditioner includes metal guarding on three sides and load-side light curtains that seize equipment operation if the sensor is tripped.

#10088-MC Bulk Bag Conditioner

The purpose of our bulk bag conditioners is to deliver the same end result – free-flowing material – but there are many ways to customize your unit to fit your facility’s needs. This construction materials manufacturer needed a durable unit with chemical-resistant fabrication that could operate continuously throughout 24-hour shifts, all while maintaining a clean and safe facility. To meet their requirements, we designed this unit to include a stainless-steel turntable cover (chemical resistance), a fan-driven hydraulic oil cooler (continuous operation), a drip-pan below the hydraulic unit (cleanliness), and four sides of operator protection including three sides of metal guarding and load-side light curtains (safety).

Applications & Case Studies

Unleashing the Potential of Material Transfer’s Conditioners

Discover how our conditioners excel across industries. Explore real-world case studies highlighting their exceptional performance, versatility, and productivity improvements. Unlock new possibilities for your material handling needs with our advanced conditioners.

Automated Conditioning Systems Helps Meet Rising Demand More Safely and Quickly

Integrated Systems: Streamlined Material Handling Operations

Experience seamless material handling with Material Transfer’s integrated systems, featuring our advanced conditioners at the core. By combining our conditioners with advanced auxiliary equipment, we deliver custom solutions to optimize your entire material handling operation.

Reliable Service & Parts

Our comprehensive range of service and parts includes installation and support, maintenance, aftermarket parts and on-site assistance. Maximize the performance and longevity of your equipment with our reliable service and parts solutions.